Augmentez la vitesse – Ralentissez – Économisez du carburant

Sélectionner le bon tracteur, la meilleure vitesse, et réduire les coups per minute (RPM) à la vitesse de rotation correcte peut générer d’importantes économies lors de l’utilisation de votre tracteur dans les opérations sur le terrain.

PUISSANCE, ÉNERGIE, EFFICACITÉ

Selecting the right tractor, setting the right gear, and reducing the throttle to the right RPM’s can spell big savings when operating your tractor in the field.

Le coût du carburant peut représenter une part importante des dépenses d’une ferme. Avec les tracteurs et l’équipement de terrain, nous pensons parfois que l’opération que nous effectuons doit toujours être faite avec le tracteur fonctionnant à un régime élevé et que des RPM inférieurs pourraient être mauvais pour le moteur et les composants d’entraînement. Ce n’est pas forcément vrai.

La taille du tracteur choisi pour une barre d’attelage légère est un bon exemple. Les petits tracteurs ont une plus grande efficacité énergétique; C’est bien connu. Lors de la traction de petites charges, ou d’exploitation d’une machine à prise de force PTO relativement légère, un petit tracteur sera toujours le meilleur choix. Toutefois, lorsque le tirage ou la résistance de la machine augmente, le dimensionnement du tracteur peut conduire à une plus grande efficacité.

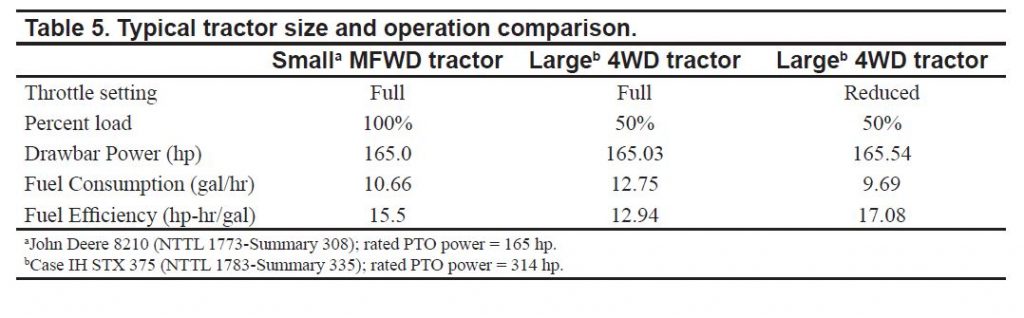

Un bon exemple de «Gear Up and Throttle Down – Saving Fuel», une publication de vulgarisation de Virginie, compare le choix entre deux tracteurs. Le premier est un tracteur cheval-vapeur de 165 tracteurs et le second est une machine à cheval-vapeur d’attelage 314. Que devez-vous faire ?:

- Utiliser le petit tracteur à plein régime et la pleine capacité

- Utiliser le grand tracteur à 50% de charge

- Use the larger tractor at 50% load but ‘gear up and throttle down’ Utilisez le plus grand tracteur à 50% de charge, mais «Augmentez la vitesse – Ralentissez».

Even though the smaller tractor has good fuel efficiency (15.5 hp-hr/gal) at full power than the larger tractor at full power (12.94 hp-hr/gal); the larger tractor actually will consume less fuel when operated at 50% power and geared up to the same ground speed as the smaller tractor in this comparison. The result was 10.66 gal/hr for the smaller tractor operating at full power, 12.75 gal/hr for the larger tractor operating at full power, and 9.69 gal/hr for the larger tractor operating at 50% power…you accomplish the same task in the same time (or even faster), and you use less fuel.

For operations that don’t require the tractor to run at full power, such as row crop cultivating, gearing up and throttling down can save a significant amount of fuel.

Ballast is a requirement on some tractors to increase the weight of the front, rear, or total axle weight, depending on the operation. Ballast will increase the tractive efficiency of the tractor when pulling heavy draft loads; but it also requires more horsepower, and can increase soil compaction. If ballasts can be removed for different operations, this can be an advantage when pulling loads that don’t require a lot of ballast. Ballast racks on the front of the tractor, or wheel ballasts can be removed when a tractor isn’t going to be expected to pull heavy drafts, and can improve fuel economy while also reducing soil compaction.

Gearing Up and Throttling Down can be a significant contributor to your variable costs on the farm while reducing the use of fuels which is more environmentally beneficial as well. This practice is suitable for light drawbar loads and jobs which won’t require the use of the power take off (PTO) shaft. PTO driven implements are set up to run at rated engine speeds for efficiency and effectiveness of the tool. You should always follow the PTO rated speed as recommended for the implement as it will adversely effect the equipment’s efficiency if not followed.

Learn more about fuel efficiency by visiting some of these sites:

“Gear Up and Throttle Down – Saving Fuel”, – Virginia Cooperative Extension

Gear Up – Throttle Down – R. Koelsch, Cornell University – Northeast Region Agricultural Engineering Society

Gear Up Throttle Down – Iowa Farmer Today

The Industry Standard for Tractor Testing is the Nebraska Tractor Test Laboratory

The Nebraska Tractor Test Laboratory – website

The University of Nebraska Tractor Test Laboratory (NTTL) is the officially designated tractor testing station for the United States and tests tractors according to the Organization for Economic Co-operation and Development (OECD) codes OECD codes. Tractors are tested in the country of manufacture. Twenty-nine countries adhere to the tractor test codes (including non-OECD members: China, India, the Russian Federation, and Serbia) with active tractor test stations in approximately 25 of those countries. Reciprocity agreements with the codes require that once an OECD test report is officially approved, it must be accepted by all participating countries.