The Secrets for Cutting Energy and Fuel Costs in Farming

The Secrets for Cutting Energy and Fuel Costs in Farming

Around the world energy costs have continued to climb both because of supply and demand constraints, as well as increasing government regulation. Energy costs constitute one of a farmers largest expenditures both in the form of direct fuel for tractors and heating and cooling structures, as well as the tandem effect of rising fertilizer costs because they are dependent on fuel costs.

When farm profits are high and there is a significant margin for the crop, fuel costs become less important. Fuel costs are generally factored to the entire operation of the farm and not necessarily associated with specific crops. This means that the crop does not get charged for the specific fuel expense required for growing crop, but rather the farm fuel costs and energy costs, out of the operating budget for the entire farm. For this reason many farmers consider the fuel costs to be a uncontrollable expense. They are seemingly saying that there is nothing that a farmer can do to reduce the costs of running the tractors and running the heating and cooling equipment, so that often farmers do not focus on reducing their energy expenses until there is a dramatic increase in the price of fuel or electricity.

Reducing Energy Costs Yields Higher Profits for Farmers

Mississippi State University researched areas where farmers could significantly reduce their energy costs. The need for reducing the energy cost became significant when there were already low farm profits and energy costs increased dramatically in a short period of time. As of this writing agricultural diesel in the United States sell for approximately $3.50 per gallon. This is roughly the equivalent of $.90 per liter.

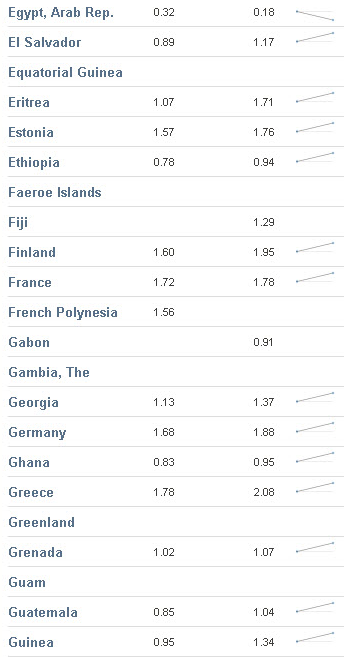

According to the World Bank survey of pump diesel prices per liter, there is an enormous invariants for farmers around the world and how much they will pay per liter of diesel.

From a low of $.18 per liter, to a high of $2.08 per liter in this short list of countries, we can see that in some countries it doesn’t matter how much energy a farmer spends, and in other countries it is absolutely critical how much a farmer spends on energy. Any of us farmers that could buy diesel for $.18 per liter would not have much to complain about in terms of our energy expenditures. But if we are closer to the dollar per liter or two dollar per liter mark then energy expense becomes an enormous burden on the profits of our farm.

Energy costs go well beyond simply the fuel farmers use for tractors. Every farm has farm buildings, periods of the year when farms either have to heat or cool products and structures, and of course the energy costs for the home for the farmer and his or her family.

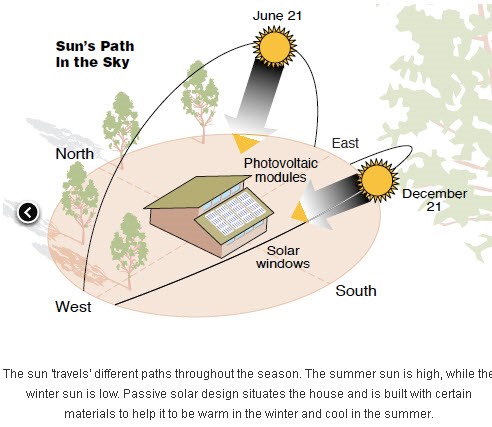

Reducing energy costs and buildings consists first and foremost of tilting with passive solar design. Passive solar design means orienting the structure so that in the coldest part of the year the building receives significant sunlight during the day to warm up the structure and in the hottest part of the year the building is designed so that the sun does not overheat the building.

Source: Greenpassivesolar.com

Passive solar design alone can virtually eliminate all heating cooling expenses in a home. If however, like most people we have a home that was already built and does not have passive solar design, then the next best thing for us is to properly reduce the energy cost of the house as it stands.

Farm Buildings Can Waste Energy if Not Sealed Well

The first thing we need to do is stop all air leaks in any of our buildings. With barns and farm structures this is an ongoing battle. With a home it is much easier because most of the leaks are focused where there are windows and doors. Even attics can have leaks and need to be taken care of with a combination of caulk, and fiber fill insulation. Caulking and weather stripping can reduce heat loss up to 37%. A 37% energy savings across the board could mean the difference between a farmer making a profit one year or losing money.

Insulation is a common method of trapping heat or cold air in or out of a structure depending on the season. R19 for walls and floors R 38 for the attic are the recommended levels. Going from R 19 to R38 will reduce heat loss in an attic by approximately 50%. Even though insulation is certainly beneficial, reducing air leaks is equally as important.

In unusually cold weather use the smallest area for each building that you can get away with. This may mean crowding in your animals into certain areas for a short period of time so that you do not have to heat the entire structure. Obviously animals will produce their own heat but this is only effective if the temperature is not significantly below freezing. The most important concept about using a smaller space is that your goal is to heat either the person in the space or the animals in the space, or the objects that you do not want to freeze or over heat. Though a simple concept, this means that you can focus all of your heating or cooling exactly where the animal or person or the structure is that you want to maintain at a certain temperature instead of heating or cooling the entire building. This small concept alone can reduce your capital outlay dramatically. No longer do you need to buy a building sized heating or cooling system, but you may be able to get away with spot heating and cooling.

Putting numbers to this cost savings reveals how significant the difference is between heating the building and heating the specific person, structure or animal in that building that you need to keep a certain temperature.

For example, if you have a structure that is 2000 ft.², then you would need approximately a 3 ½ ton air conditioning unit to cool that area. If instead you only cool the area where you have occupants in that structure and section off that area, then you may be able to get away with cooling only 500 ft.² of the entire 2000 ft.² structure. This approach would allow you to get a less than 1 ton air conditioning unit for the 500 ft.² area. Running a 1 ton unit will save you approximately 70% in energy costs over running the 3 ½ ton unit. As you can see from this example the results of using this simple principle of heating and cooling exactly what you need the right temperature as opposed to the entire structure saves not only an enormous amount in the upfront capital costs of your heating and cooling system but also the ongoing energy expenditures. Both capital cost and energy expenditures are heavy burdens for a farmer. Every opportunity for reducing capital cost that does not require loans or significant cash outlay is a positive thing for the balance sheet.

Using Alternative Energy Sources

Farm tractors can use gallons of oil every month for lubrication. Rather than giving the oil away for recycling, more advanced farmers are filtering the oil and then processing it slightly and using it as fuel for the tractor. Though 15 gallons for a diesel tractor does not go a very long way, month after month it builds up into a significant cost savings. Used motor oil from all the farm vehicles can also be employed in heating structures with oil heating stoves. As YouTube shows, many people build their own simple waste oil heaters out of items including old brake rotors, former wood-burning stoves, and copper tubing. It is also possible to buy advanced wood-burning stoves from companies like clean burn.com and many others. The key point is that every resource that can be used as energy on a farm must be used as energy. Profits are made by both increasing revenue and also decreasing expenses. Both of these efforts will show up as profits. Decreasing expenditures can be much easier at times, especially when it comes to energy and recycling, then increasing revenues.

If you decide to burn used motor oil in your tractor or other diesel vehicles, it is a good idea to take the motor oil through several filtration steps and then to mix it with standard diesel. Some people start out with as little as 10% used motor oil and 90% diesel, others will run as high as 100% used motor oil only if they have heavily filtered the oil and processed it significantly as well as tested it to make sure that it will not clog the modern fuel injectors. One time of clogging the modern fuel injectors in either your tractor or your farm truck, will cost you more than almost a lifetime of saving your used motor.

Maintaining heating and cooling equipment also will improve energy efficiency but not dramatically so. And less you have not changed your HVAC filter system in quite a while, the efficiency gains will not be that significant.

Heating and cooling structures is one of the greatest energy expenses for the buildings and for a farm residence. The other energy expenditures occur in the field.

Another method of using alternative energy include using solar power pumping stations and solar power for light duty electricity usage. More than likely you will still need to have generator backup for heavy-duty at electricity usage that may include processing equipment, fabrication equipment, and large-scale heating and cooling. The problem with alternative energy in the form of solar power is that there is usually a very large upfront cost in both the photovoltaic solar cells and the batteries and ancillary equipment required to make use of the electricity the solar cells generate. In less you are being subsidized for the purchase of the solar power rate you may find that the electricity savings takes as long as a decade or more before it pays off for the solar power system.

Minimizing Energy Expenditure Out in the Farm Field

The number one thing that a farmer can do to reduce energy expenditures in the field is to reduce the amount of tilling. No till farming offers significant benefits over repeatedly tilling the soil. One of these immediate benefits is that the tractor no longer has to drive hard over the ground and eat up a lot of diesel. Also, no till planting method ends up saving not only money but can increase the vitality of the soil. The best way to use the no tilling method is to simply plant a cover crop that fixes nitrogen into the soil. Good cover crops for this are vetch, alfalfa, peanuts, and clover. Some farmers rotate soya in as well because it is both a cash crop and a good nitrogen fixer in certain cases.

Beginning with the no till approach another good addition is managing the nutrients in the soil. Minimizing the amount of fertilizer that you have to buy every year will save both the distribution costs of the fertilizer as well is the direct cost of purchasing amendments. One method of ensuring that you are not over fertilizing and fertilizing appropriately is to repeatedly test your soil. If possible, the best way to test your soil is to have automatic wireless testers planted throughout your acreage. They will give you an update as to the condition of both the plants and the soil without your having to run soil sample tests yourself.

Even though you may practice good no till farming techniques and test your soils, you will more than likely still have to apply some nutrients to your crops. If you use advanced nutrient application technology that sprays directly on the crops, does not overspray, and avoids spraying in the areas where there are no crops, you will maximize your energy expenditure and your nutrient application.

Reducing Energy in Grain Drying Operations

Drying grain can be an energy intensive operation. Because so much energy is required for drying grain, it also presents an opportunity for saving significant energy if you decide to allow the grain to dry in the field. The problem with allowing grain to dry in the field is that you may end up lowering the quality of your crop. For corn you may develop aflatoxin if you leave the corn in the field. Energy savings cannot justify ruining your crop.

An easy method for reducing your energy expenditure when you’re storing your crop in your grain bins is to make sure that the plenum or enclosure under the floor of the grain bin is completely clean. This will allow the airflow to try out the grain much more easily than if that area is clogged.

Irrigation is another area where you can save a significant amount of money simply by changing the timing of when you irrigate. The best time to irrigate is before the soils are completely dry. Also, all of the tires for your irrigation platform the chains, the pumps, and all the engines must be completely lubricated and maintain well. This will allow the irrigation system to traverse with a minimal amount of effort and reduce your energy costs significantly.

Storing fuel and energy gives you great options for cutting costs

This past year in the United States propane was in such short supply that many states declared propane emergencies. Those people that had large storage tanks with over 500 gallons of propane, and had been wise enough to fill them when the prices were very low, had almost no problem as they got through the winter season without requiring additional propane. Those that did not have the storage tanks or had not been wise enough to purchase propane when the price was low and it was available, found themselves in this scary situation of both having to pay three and four times the normal cost for propane while wondering if they could get it.

The lesson from this important story is that a farmer must have significant storage of all critical fuels for their operation. Not only does this allow a farmer to ride out periods of low supply, but also allows a farmer to buy more than they would normally need when the prices are low. Any money spent in storage tanks is money well spent. Propane never goes bad and diesel fuel can be stored with preservative chemicals for as long as six years if it is properly conditioned prior to storage. Storing gasoline is unsafe in quantities over more than 25 gallons usually. For this reason it is important that a farmer has multiple propane storage tanks if at all possible, as well as at least one storage tank for diesel in the area of 100 gallons. Considering that many tractors require 30 and 40 gallons or more for a fill up, 100 gallons does not give a farmer a significant storage of diesel but perhaps enough to ride out a week or two of short supply or high prices.

Also, shopping for different fuel suppliers can save a tremendous amount of money over the long haul. Fuel prices can vary as much is 15 or 20% in just small geographic areas. As shown in the chart of the prices for diesel fuel from different countries, there are also variances simply one city to a next. And if you happen to have a decent sized storage tank, you can load up the tank onto your pickup truck and make it worthwhile to buy diesel that is perhaps 20 or 30% cheaper a neighboring town.

Last but not least there are new forms of tractor technology that may dramatically increase the efficiency of tractors. One of the number one types of technology that is already out there is the hydrogen powered tractor. No longer do farmers have to worry about having enough diesel, instead they can use hydrogen balls that look like charcoal almost, and will power a tractor for weeks on end. Other forms of hydrogen tractor technology will use natural gas. Though they may be cheaper to run per fill up, the energy density of natural gas is not as high as for diesel and consequently the tractors will not have the range.

A hydrogen powered tractor is essentially an electric motor powered tractor where hydrogen is transformed into electricity with a fuel cell. New Holland’s NH2 Hydrogen Powered Tractor boasts an impressive 106 hp motor. Electric motors have enormous torque for their horsepower. This means that hydrogen power tractors are more than likely going to perform as though they have much higher horsepower then their nameplate rating. In the future, farmers will have far more choices in terms of how to power their tractors, and the rest of their farm.

For the time being though it still pays to take the time and use every ounce of available energy from the resources you are a purchase as well as making sure none of that energy gets wasted in your buildings, or in your process.